Recently, the "China Intelligent Manufacturing Development Research Report: Capability Maturity" (hereinafter referred to as "CMMM 2.0"), co-authored by the China Electronics Technology Standardization Research Institute and related units including Futong Dongfang, was officially released.

CMMM 2.0, with the flexible application of CMMM as its theme, innovatively proposes that CMMM is a flexible model that is decomposable, combinable, and configurable. Starting from the perspective of enterprise application, it elaborates on the connotation, principles, and application value of CMMM, guiding manufacturing enterprises of different types and industries to consider intelligent manufacturing planning from a systematic and holistic perspective, and to choose the correct path to implement intelligent manufacturing process improvement work. It provides theoretical references for enterprises to continuously enhance the level of intelligent manufacturing capability maturity. Based on the construction needs of smart workshops, smart factories, and intelligent supply chains at three levels, CMMM 2.0 proposes an in-depth approach to empower the construction of intelligent manufacturing projects, guiding enterprises to anchor their business goals and efficiently implement intelligent construction following a systematic roadmap.

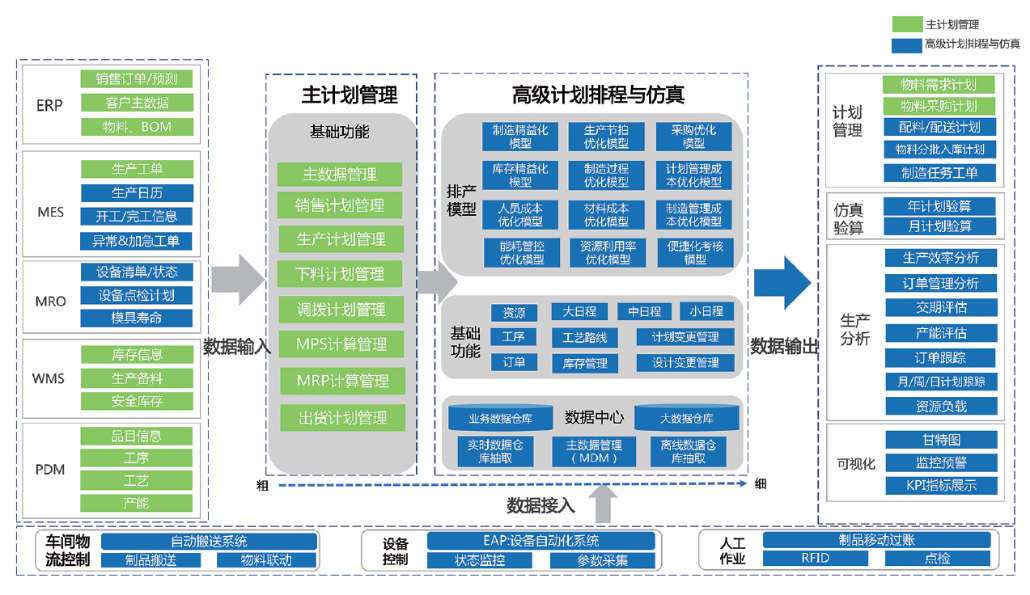

At present, the production scheduling of enterprises involves multiple departments. The traditional paper-based information transfer mode has low real-time performance, the material kit completeness is difficult to control, and the production progress and machine load are not transparent, which can easily lead to delivery delays. At the same time, factors such as customer order cancellations, rush orders, and equipment issues can lead to unreasonable production scheduling and equipment idleness, resulting in resource waste and increased production and operational costs.

In response to these issues, within CMMM 2.0, Futong Dongfang has provided practical pathways for flexible production scheduling from the aspects of systematizing production planning management, coordinating planning and production management, and intelligentizing planning and scheduling. This offers practical guidance for enterprises to continuously enhance the maturity level of intelligent manufacturing capabilities.

This includes meeting market and customer-specific demands, monitoring all production elements in real-time, setting up various constraints and strategies to form multiple production scheduling plans, maximizing the allocation and utilization of resources, and dynamically issuing detailed work plans. Additionally, it involves timely early warning for production exceptions, automatically adjusting current planning tasks based on the type of exception, or automatically providing recommended solutions for manual confirmation.

Flexible production scheduling architecture diagram

In the era of intelligent manufacturing, Futong Dongfang's independently developed Intelligent Advanced Planning and Scheduling Platform (iAPS) is driven by AI technology and features intelligent collaboration in rule-based scenarios. It refines production management to the workstation level and breaks through the limitations of traditional manual and software-based scheduling. Even when facing issues such as process optimization, process adjustment, urgent order insertion, and market surges, it can still quickly and accurately provide the best production planning instructions.

Currently, Futong Dongfang's Intelligent Advanced Planning and Scheduling Platform (iAPS) has been applied in the automotive industry, 3C industry, and mechanical equipment manufacturing industry, with typical applications that have led to an increase in material kit completion rate by more than 5%, an improvement in on-time delivery rate by more than 10%, a reduction in auxiliary costs by more than 10%, and a reduction in scheduling implementation time from 2 hours per instance to 5 minutes per instance.

To implement the "14th Five-Year Plan for Smart Manufacturing Development" and to promote the transformation and upgrading goal of significantly enhancing the maturity level of smart manufacturing capabilities in manufacturing enterprises, Futong Dongfang will, in the future, integrate its own technological innovation and business practices. It will also collaborate extensively with industry peers to provide guidance on the path to enhancing smart manufacturing capabilities across more industries and fields. The company aims to create an understandable, navigable, and applicable guide map for the improvement and enhancement of smart manufacturing for enterprises.